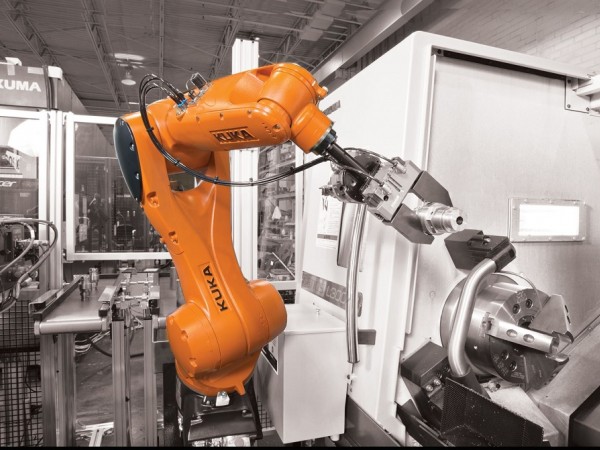

Our portfolio offers perfectly matched automated solutions for more efficient manufacturing and warehousing processes – from just a single industrial robot to specialized robotic cells and complete robotic system concepts. Here you will find an overview of different industrial robots application in different industries.

IMPORTANT ADDITIONAL ELEMENTS OF ALL ROBOTIC SOLUTIONS

The robot periphery is a factor that must not be underestimated when considering the efficiency of your production processes. With end effectors, energy supply systems, linear units, and positioners, you can considerably expand the functionality of every industrial robot. STAMH offers additional modules for all payload categories, for full automation and human-robot collaboration. We will happily advise you on the selection of the right additional module for your robot.

Industrial robots have been solving the problems of the end customers, and ensuring their success, with efficient, state-of-the-art automated solutions.

APPLICATIONS OF THE INDUSTRIAL ROBOTS IN LOGISTICS, INDUSTRIAL AND WAREHOUSING PROCESSES

PALLETIZING ROBOTS

Industrial palletizing systems must operate at high speed and with minimum interferences. They are extremely strong and durable. KUKA industrial robots can work in harsh and adverse industrial conditions and for longer periods of time, up to 24 hours per day. These industrial robots are specially designed to perform palletizing and depalletizing tasks, lifting heavy loads from 40 kg. to 1300 kg.

Learn more about the palletizing systems that STAMH Group designs and implements, with the best-in-class components and industrial robots.

PACKAGING ROBOTS

This type of industrial robot must be extremely flexible. KUKA robots are able to handle even delicate goods. Packaging robotic systems can perform various functions like placing products in boxes, cassettes, or trays, labeling, box sealing, sorting, and re-ordering ready-for shipment SKUs.

SORTING ROBOTS

Velocity and the lack of errors are the main reasons why more and more businesses decide to implement sorting lines, with robust industrial conveyor systems and sorting robots. Automated sorting leads to a dramatic increase in productivity combined with reduced operational costs.

ASSEMBLY AND MOUNTING ROBOTS

This type of industrial robots are able to perform different repetitive tasks, as well as handling various tools. STAMH Group recommends the implementation of such industrial robots whenever there is a need for high-frequency assembling, requiring speed, and precision.

INDUSTRIAL ROBOTS FOR WELDING, CUTTING, AND GRINDING

This type of industrial robots often replace industrial operators due to adverse working environments, extremely high or low temperatures, and many more. The working area and coverage of these industrial robotic solutions can reach more than 3 meters, depending on the type of KUKA robot you choose.

PAINTING ROBOTS

Industrial painting robots have a wide range of applications. They are able to work with different paintings, primers, and a large variety of coatings. A larger axis number of a KUKA robot means more flexibility.

KEY BENEFITS AND REASONS TO IMPLEMENT A NEW ROBOTIC SYSTEM

-

Ability to work at too low or high temperatures;

-

Perfect functioning in dusty or adverse environments;

-

Ability to design robotic systems and cells, including industrial robots, conveyor systems, and automated machines with a single and unified control system;

-

Large payload capabilities and wider range, depending on the industrial robot you choose;

-

Increased efficiency and quick return on investment;