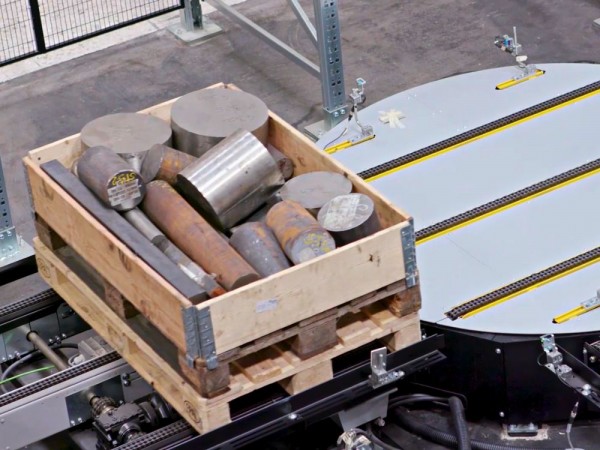

STABLE AND ROBUST SOLUTION FOR HEAVY GOODS AND LOADS

Chain conveyors and conveyor systems are used to move and transport heavy palletized loads, or massive containers with a solid base. STAMH Group installs them in industrial and industrial environments, warehouses, and distribution and logistics centers;

Chain conveyors ensure stable, reliable, and organized transportation and high productivity. They efficiently replace manual work, avoid human errors and reduce the distances covered by the material handling machines;

MAIN TECHNICAL CHARACTERISTICS OF THE CHAIN CONVEYOR SYSTEMS

The efficient operations of the chain conveyors is based on the perfect matching of the used components - chain strings (the number of which is selected depending on the type of goods), drive shafts, chain wheels, as well as special plastic or metal profile to increase the safety of the intralogistics transportation tasks;

Depending on the specific needs, chain conveyors can be equipped with additional elements, including side guides, collectors, and plastic and rubber coatings, which increase the efficiency and capabilities of chain systems for intralogistics transport;

- 2,3 or 4 chains;

- Inclination of up to 4% according to the specific needs;

- Operational temperature ranges from -28 to +45 C;

- Integration in warehouses or distribution centers with special storage conditions;

- Speed from 0.1 to 0.5 m/s;

- Loading capacity of more than 1875 kg

ADVANTAGES AND FUNCTIONALITIES OF THE CHAIN CONVEYORS AND TRANSPORTERS

- Precise and reliable transportation of heavy SKUs and pallets;

- Special platforms for 360° rotation in the system;

- Achieving high-performance processing of heavy palletized loads;

- Comprehensive, integrated, and energy-efficient solution;

- Constant and organized pallets flow, with controlled speed and intensity;

- Robustness, strength, and stability;

- Significant reduction of the distances that lifting equipment must cover;

- Automation of intralogistics transportation processes;

- Perfectly functioning in oxygen-reduced environments or refrigerated warehouses, with reduced lighting levels;

- Operational costs reduction end efficiency;