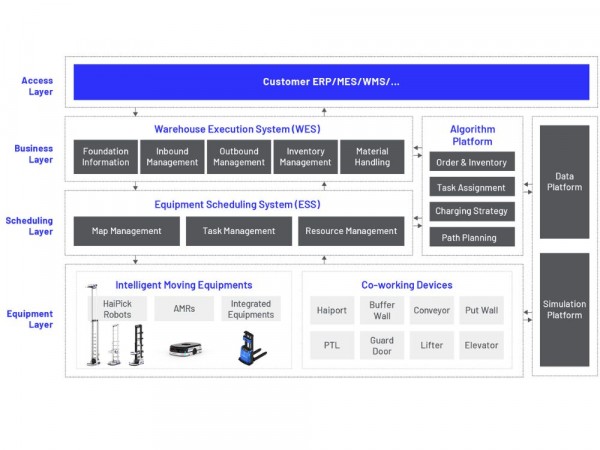

Designed with a modular architecture and powered by AI algorithms, this order fulfillment software ensures seamless integration, dynamic configuration, and continuous optimization of operations within the distribution center.

SOFTWARE ARCHITECTURE AND MODULES OF THE HAIQ ORDER FULFILLMENT SOFTWARE FOR THE AUTOMATED HAIPICK INTRALOGISTICS SYSTEMS

HaiQ consists of five core modules, each playing a key role in overall system control and performance optimization:

Warehouse Execution System (WES)

Connects with internal systems such as ERP, WMS, or MES and manages inbound, outbound, inventory, consolidation, and order processing operations. Supports various strategies such as order batching/splitting and multiple other fulfillment strategies – for example, grouping orders with similar products - known as wave picking - as well as allocating the heaviest workloads to the most efficient workstations - heat strategies. The software delivers performance of up to 10,000 external requests per second and provides encrypted communication between ACR and AMR robots.

Equipment Scheduling System (ESS)

This layer controls robots, equipment, and the physical infrastructure. It supports integration with various devices – HaiPick systems, HaiPort, HaiFlex, Conveyors, Pick-to-light Systems – and enables parallel operation of different AGV and AMR robots.

- Large-scale management: up to 1,000+ robots simultaneously;

- Smooth and efficient operations without idle waiting between devices.

Data Platform

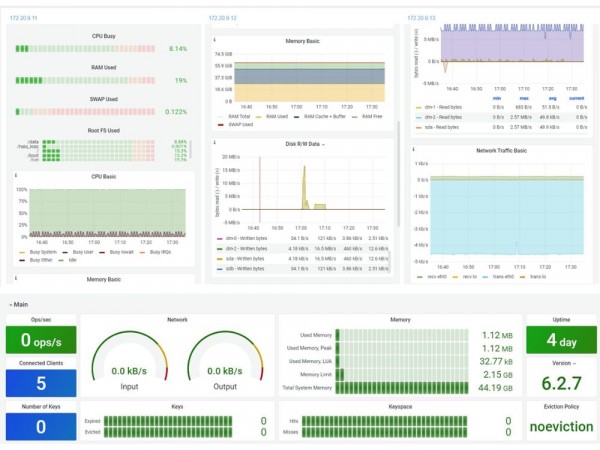

Collects information from WES, ESS, robots, staff, and goods, and presents it through user-friendly visualization interfaces. This gives management clear insights into workload, traffic, and achieved efficiency. It ensures transparency and provides the foundation for managerial decisions and adjustments.

Simulation Platform

Creates a digital twin – a real warehouse in a virtual environment, using maps, order files, inventory, and requirements. It allows testing and validation of strategies, configurations, and decisions in a 1:1 environment compared to reality, ensuring maximum effect.

AI Algorithm Platform

This is essentially the intelligent brain of every automated HaiPick Autonomous Picking System:

- Order allocation algorithms balancing execution accuracy with maximum efficiency;

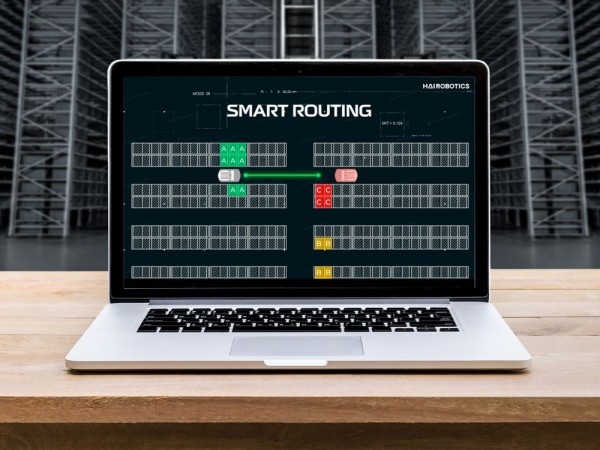

- Task assignment algorithms for robots, calculating optimal timing and minimal path;

- Route planning to minimize movement, avoid collisions, and reduce downtime;

- Charging algorithms to maintain continuous robot readiness.

HOW DOES THE HAIQ SOFTWARE FOR AUTOMATED HAIPICK FULFILLMENT WAREHOUSE SYSTEMS WORK

-

Integration with existing systems — WES receives requests from ERP/WMS/MES, distributes tasks, configures workstations, and creates optimal strategies, while processing massive amounts of dynamic data

-

Robot orchestration — ESS sends instructions to robots and equipment, organizing parallel workflows and large-scale warehouse operations;

-

Data-driven management — The Data Platform provides transparent indicators of the current state of the warehouse, operations, and orders.

-

Optimization through simulations — The Simulation Platform tests projects and strategies before they are implemented in the real environment, allowing management to make informed and correct tactical decisions.

-

AI control — AI algorithms analyze, plan, and execute, ensuring stable resource and time management.

KEY BENEFITS OF IMPLEMENTING HAIQ SOFTWARE FOR AUTOMATED FULFILLMENT SYSTEMS

- Maximum operational efficiency

Configurable strategies, optimized routes, and intelligent charging ensure smooth and productive operations; - Flexibility and reliability

The modular architecture allows dynamic adaptation. Automatic resilience guarantees stability even in case of errors; - Integration with any software infrastructure

Connects with all existing WMS/WES solutions and co-manages robots and systems without the need for complete replacement; - Real-time visibility and transparency

Interactive data visualizations and metrics keep decision-makers informed and empowered; - Pre-implementation testing

Simulations enable early testing and optimization, avoiding mistakes and accelerating ROI; - AI-driven control

Bold decision-making, planning, and execution — without human errors, and in real time;

WHY CHOOSING HAIQ IS A STRATEGIC DECISION

- Comprehensive solution compatible with any existing system;

- Exceptional resilience and scalability;

- Increased productivity and speed;

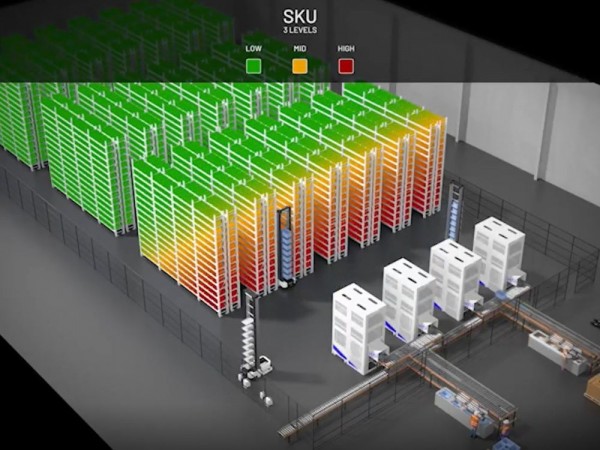

- Better utilization of space and resources;

- Data-driven and intelligent management.