VERTICAL SPACE OPTIMIZATION - RECLAIMING YOUR FLOOR

In an era of soaring real estate costs, the HaiPick Climb System’s core value lies in its ability to maximize cubic storage capacity. Engineered to utilize the maximum available ceiling height, this AS/RS solution offers a dramatically reduced operational footprint. Businesses can now reclaim up to 70% of floor space, redirecting this valuable real estate to expansion, staging, pallets storage or other value-added manufacturing processes. This is not just automation - it's capital preservation through intelligent vertical integration and high-density storage;

BREAKTHROUGH THROUGHPUT - DRIVING GOODS-TO-PERSON EXCELLENCE

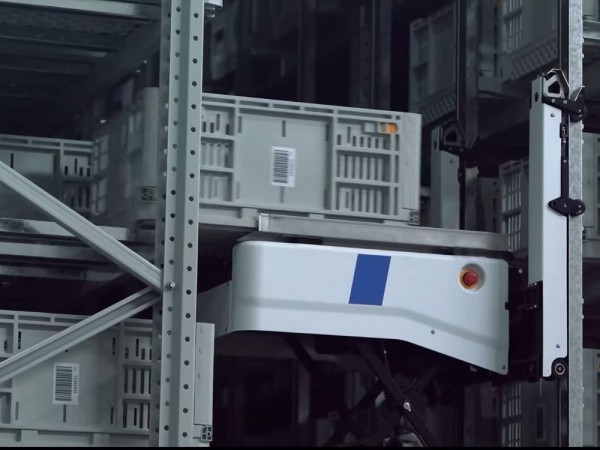

The primary metric of success in modern logistics is speed. The HaiPick Climb System ensures operational excellence by embodying the Goods-to-Person (G2P) principle. The autonomous system - using precision-guided HaiPick Climbing Robots - delivers picking totes directly to operators. This systematic approach eliminates manual travel time, and order picking bottlenecks, resulting in unparalleled cycle speeds and pick rates! For facility managers, this means predictable, continuous operational flow and a clear, accelerated ROI fueled by continuous productivity gains;

OPERATIONAL COST REDUCTION - SECURING LABOR STABILITY

Persistent labor shortages and escalating wage costs demand automated solutions. The HaiPick Climb System directly addresses this volatility by requiring minimal human intervention for core storage and retrieval functions. Its autonomous operation translates directly into significantly lower, predictable operating expenditures. By relying on precise, machine-controlled movement, the system also minimizes inventory damage and virtually eliminates handling errors, while simultaneously improving the overall safety of the work environment. The result is a highly stable, low-risk, and cost-efficient operation;

| Automated HaiClimb System Technical Specifications | ||

| Category | Specification | Technical Data (Metric Only) |

| Storage Density | Max Storage Height | Up to 12 meters |

| Aisle Width | As narrow as 900 mm | |

| Storage Locations | Up to 30,000 storage locations per 1,000 m² | |

| Footprint Reduction | Storage footprint reduction of up to 75% | |

| Performance | Max Throughput | Up to 4,000 totes per hour (in a 1,000 m² space) |

| Order Fulfillment Time | Totes delivered to workstations in as little as 2 minutes | |

| HaiClimber Robot | Order Picking Accuracy | 99%+ pick accuracy |

| Max Ground Speed | Up to 4 meters per second | |

| Max Climbing Speed | Up to 1 meter per second | |

| Robot Fleet Size | Scalable fleet sizes up to 3,000 robots | |

| Operation | Continuous 24/7 operations (with self-charging) | |

| Infrastructure | Racking Compatibility | Compatible with most standard cross-bar racking |

| Climbing Mechanism | Single-sided guide rail with two climbing arms | |

| Installation Environment | Designed for low-precision floors, simplifying installation and retrofitting. | |

| Software | System Control Platform | Managed by the HaiQ platform (supports seamless WMS/ERP integration) |

| Payload | Handling Capability | Supports plastic totes and carton boxes |