HIGH PERFORMANCE AND EASY INTEGRATION

HaiClimber is an innovative robot used within the HaiPick Climb warehouse system, specifically designed for automated goods picking in distribution and logistics centers. It operates within Industrial Racking, climbing along a guide rail, and requires minimal infrastructural modifications;

KEY TECHNICAL FEATURES OF HAICLIMBER

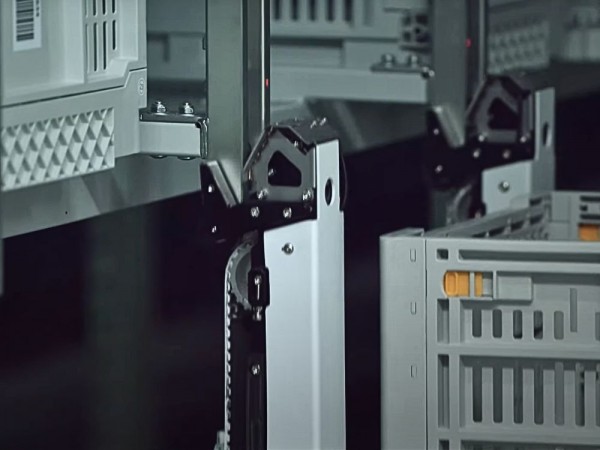

- Climbing and descent mechanism: Operates via two climbing arms that connect to guide rails on one side of the Racking System;

- Horizontal movement speed: Up to 4 m/s;

- Vertical movement speed: Up to 1 m/s;

- Fleet capability: The system supports up to 3,000 robots with automatic charging for uninterrupted 24/7 operations;

- Installation: Compatible with industrial racking up to 12 m in height, requiring only minimal floor leveling;

STORAGE DENSITY, SPEED AND HIGH THROUGHPUT

- Performance: Up to 4,000 picking totes/hour within a 1,000 m² operational area;

- Tote delivery time: ≤ 2 minutes from request to workstation;

- Faster than traditional ASRS: Up to 34% faster in operations;

- Maximum storage density: Up to 30,000 tote locations in 1,000 m² at heights up to 12 m – up to 6 times more than traditional storage systems;

- Racking aisles: Narrow aisle widths down to 900 mm, increasing storage area usage by up to 75%;

SYSTEM SOFTWARE AND PERIPHERALS

- Workstations - ergonomically designed picking stations with intuitive user interfaces, ensuring up to 99% picking and order assembly accuracy;

- HaiQ Software - intelligent fleet and task management, real-time data tracking and analytics for continuous operational optimization;

APPLICATIONS AND INTEGRATION OF HAICLIMBER ROBOTS

HaiClimber is a core component of the HaiPick Climb system and is ideal for:

- Distribution centers in key industries and sectors such as e-commerce, fashion, 3PL, retail, food, healthcare products, electronics, and automotive components;

- Simplified integration, as the HaiClimber system can be adapted to both new and existing facilities with minimal structural modifications;

BENEFITS AND FULL WAREHOUSE PROCESS OPTIMIZATION

-

Minimized or eliminated human movement in the picking process, fully implementing the goods-to-person principle – reducing time losses and physical strain in the warehouse;

-

Significantly increased operational efficiency – up to 4× faster order processing and 3× higher daily throughput;

-

Scalable and cost-effective automation solution compared to traditional ASRS Systems, requiring less infrastructure preparation;