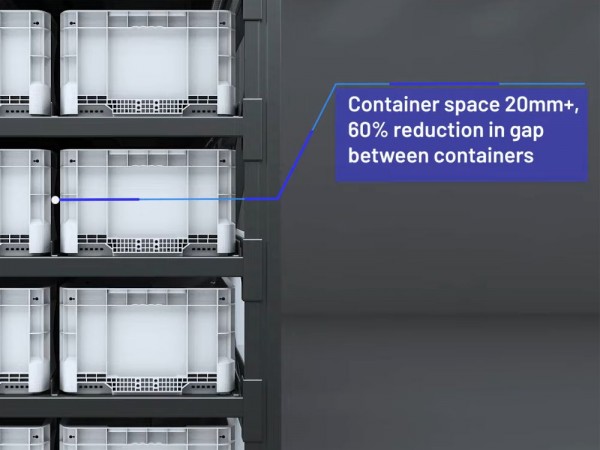

HaiPick A42-E6S Autonomous Case Picking Robot is an advanced autonomous robot that delivers a new level of efficiency in automated picking containers handling. With a payload capacity of up to 300 kilograms and an innovative design, the robot can reach depths of one to three positions. The HAIPICK A42-E6S series is designed to offer higher storage density and reduce order fulfillment time in warehouses while increasing the overall productivity of the Automated Warehouse System. The improved architecture allows containers to be placed closer together, with a minimum horizontal spacing of just 30 millimeters and zero millimeters between picking containers in depth. This means up to 150% more efficient use of available space compared to similar solutions.

HaiPick A42 E6S achieves up to 30% higher operational productivity thanks to shorter cycle times and optimized motion and picking algorithms. The robot is designed with ease of maintenance in mind – easy disassembly and compact design lead to a 10% reduction in transportation, delivery, and servicing costs.

GRAPPLING HOOK MECHANISM OF THE AUTONOMOUS ACR A42 E6S PICKING CONTAINERS HANDLING ROBOT

One of the key innovations in this model is the use of a special grappling hook mechanism instead of a standard lifting element:

- More efficient handling of heavy loads;

- Operations in tight spaces;

- Fixation of containers by physical limiters, eliminating the need for QR codes to position the containers themselves (not the robot);

NAVIGATION SYSTEM OF THE AUTONOMOUS ACR HAIPICK A42-E6S ROBOT

- LiDAR sensors for spatial orientation and obstacle detection;

- Autonomous guidance to the robot’s charging station;

- Safety systems including emergency stopping and intelligent motion control.

MAIN ADVANTAGES OF THE HAIPICK A42-E6S ACR PICKING ROBOTS

- Handling up to three picking containers in depth, providing more storage space without the need to expand the warehouse;

- Payload capacity of up to 300 kg, with standard single loads of 30 kg and customization up to 50 kg if needed;

- Improved operational efficiency – up to 30% shorter cycles and higher processing speed;

- Reduced operating costs through modular design and easy disassembly;

- No QR codes needed – orientation of the grappling hook for storing and retrieving picking totes via physical limiters for greater reliability;

- Autonomous movement and safety – intelligent navigation, obstacle avoidance, Wi-Fi connectivity, and automatic charging.

HAIPICK A42-E6S ACR PICKING ROBOTS ARE SUITABLE FOR A WIDE RANGE OF INDUSTRIES

The HaiPick A42-E6S Picking Containers Handling Robots are applicable across various sectors including e-commerce, automotive industry, pharmaceuticals, electronics, retail, and 3PL. Regardless of scale, this robot optimizes logistics processes and significantly increases warehouse efficiency;