100% PICKING AUTOMATION AND ORDER PROCESSING IN THE WAREHOUSE

This modification of the Vertical Lift Machines is particularly suitable for warehouses searching for the higher possible automation levels. The OnePick VLM machine extracts the desired tray and also - the box, carton, or picking cassette itself – without human intervention. This practically means 0 picking errors and 0 errors when preparing the next order;

APPLICATIONS OF THE ONEPICK VERTICAL LIFT MACHINES

Vertical Lift Machines are self-supporting automatic vertical structures suitable for buffering a large amount of packaged or unpackaged, non-palletized goods and items. Stored goods are organized in trays, placed one above the other. These vertical warehouses can be quickly adapted to Your specific needs and inventory – the height of the machine varies according to the size of the warehouse and the number of products You need to store and process faster;

THE VLM ONE-PICK MODIFICATION IS VERY SUITABLE IN MANY SPECIFIC CASES

- When you need equipment for fully automated zones in the warehouse;

- In unhealthy and adverse working environments;

- When working with dangerous materials;

- When working in locations with less light;

- Outlying areas, located far from the zone where the products are needed;

- When you need to integrate the VLM with a smart and dynamic conveyor system;

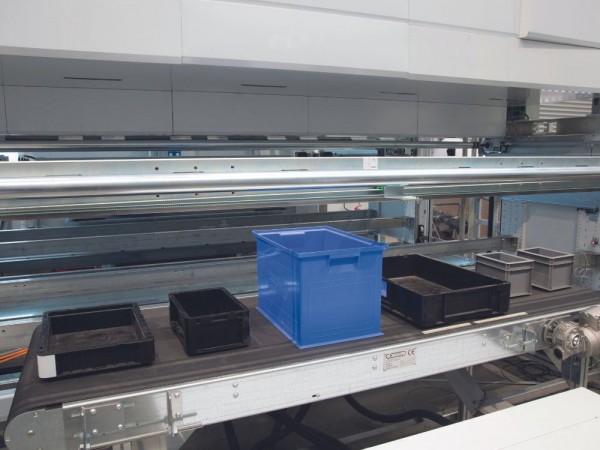

With OnePick vertical warehouses, the picking bay is positioned at a specific, predefined height. Thus, the VLM machine automatically retrieves and places the cassettes, boxes, and cartons on roller or belt conveyors. They transport all the goods to the desired area in the warehouse or the distribution center. To automate the entire process, you simply need to sketch the trays of the automated vertical warehouse when loading the machine;

SMART AND DYNAMIC TRAYS DISTRIBUTION TO OPTIMIZE SPACE

The Dynamic Trays Distribution function of the VLM machine automatically distributes the trays in the machine depending on the free space and the height of the stored items. This allows maximum and automatic space optimization in each VLM module installed;

On the other hand, the integrated WMS - Warehouse Management Software is the heart and brain of the OnePick lift machine. It sketches the position of the containers, boxes, or cartons on the trays and directs the automated gripper which brings out the required box or cassette with items;

The VLM extracts the selected tray and then, also picks the SKU with special clamps in a fully automated way. Then, the products can be transported by roller or belt conveyors and conveyors to the desired area in the warehouse or the distribution center;

WHAT DO YOU GET, IF YOU CHOOSE THE ONEPICK AUTOMATED VERTICAL LIFT MACHINE?

- You can always add additional upgrades like tray accessories, partitions, and dividers. They give you the complete freedom and agility to arrange the stored items in the most suitable way;

- Additional accessories are easy to modify, and the Automated Vertical Warehouse adapts quickly to the current needs of Your business;

- Tracking, reporting, and exact records of every single warehouse operation;

- Secure storage and limited access;

- Automated picking and orders processing;

- Dynamic trays distribution in the vertical storage machine - the software automatically detects the height of each tray and distributes the internal volume in an optimal way - without empty spaces;

- STAMH Group can design and implement Vertical Lift Machines with different heights, lengths, and depths of each tray, depending on your specific needs;

|

SELECTION OF ONE PICK VERTICAL LIFTS |

|

МА and MA - D |

|

MC and MC - D |

|

MX and MX - D |

|

ML and ML - D |