HaiPick System 2 expands the capabilities of HaiPick System 1 by combining the automated handling of standard picking totes with bulk goods and pre-staged palletized items. This makes it ideal for warehouses with a diverse product assortment and high efficiency requirements. The Automated HaiPick System 2 delivers up to 6 times higher productivity and significantly optimizes warehouse space utilization.

HOW HAIPICK AUTOMATED WAREHOUSE SYSTEM 2 WORKS

The 100% Automated HaiPick System 2 uses two types of robots working together in a mixed, software-integrated intralogistics environment:

-

ACR Robots /Autonomous Case-handling Robots/ - Autonomous robots that handle picking totes in storage areas with racks up to 12 meters high. They can access up to two totes in depth and automatically pick and transport containers to workstations in the fulfillment center;

-

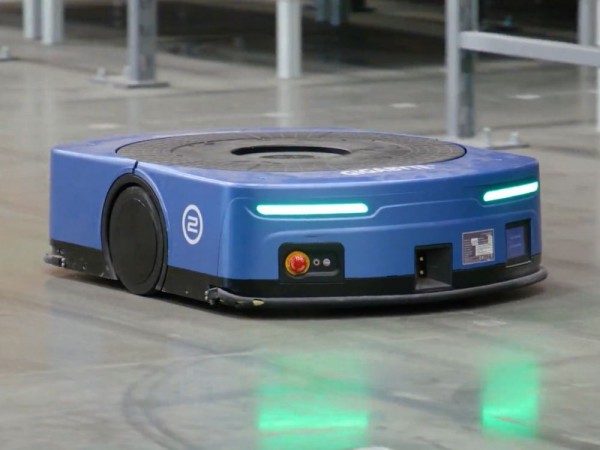

AMR Robots /Heavy-Duty Companion AMRs/ - Flat-platform robots designed for transporting larger or irregular items, including bulk goods and goods that have been pre-loaded onto pallets;

KEY FEATURES AND ADVANTAGES OF HAIPICK AUTOMATED WAREHOUSE SYSTEM 2

-

Mixed and autonomous picking, handling, transportation, and orders assembly

Supports combined flows of small containers, bulk items, and palletized units within the single Automated Fulfillment HaiPick System 2; -

Scalable and flexible architecture of the HaiPick System 2

Enables step-by-step deployment - from small-scale implementation to full warehouse automation. Compatible with various Racking Systems, standard picking totes, and palletized loads; -

Integration with existing infrastructure

Doesn't require complete replacement of current equipment. Can be integrated with existing racks and containers that meet technical specifications - subject to prior analysis and assessment by STAMH Group experts; -

HaiQ Software Platform

Centralized control of all robotic units, process visualization, intelligent routing, resource management, and integration with WMS for warehouse and logistics operations. -

Ergonomic workstations

Inbound and outbound stations are ergonomically designed to ensure comfort, speed, and precision during human-robot interaction. This improves productivity while significantly reducing operator strain. -

Continuous operation and safety

Supports 24/7 operation with intelligent charging, built-in collision protection, and certification under internationally recognized standards – CE + NRTL.

SUITABLE APPLICATIONS OF THE HAIPICK AUTOMATED WAREHOUSE SYSTEM 2

HaiPick Automated Warehouse System 2 is an effective solution for:

- Fulfillment centers with diverse product ranges;

- Warehouses handling both small and bulky items;

- 3PL operators serving a wide variety of clients and SKUs;

- E-commerce warehouses with high turnover and demand for flexibility;

- Manufacturing warehouses requiring transport of both light and heavy materials;