Client: Papadeas S.A., a leading distributor of industrial tools and hardware across Greece and the Balkans, has successfully modernized its warehouse operations with a next-generation escala automation solution delivered by STAMH Group. With increasing demand and a growing variety of SKUs, the company needed a system that could handle complex order fulfillment, streamline inbound logistics, and accelerate delivery - all while remaining flexible and scalable;

Location of the project: The company’s warehouse in Athens serves as a strategic logistics hub, combining Conventional pallet storage with advanced automation for non-palletized goods;

Challenge: To meet the challenge of managing thousands of small items and diverse order profiles, STAMH Group implemented a hybrid solution featuring a new Automated 3D escala System, and a powerful software suite designed to orchestrate every movement within the warehouse;

Solution provided: At the core of this transformation is a multi-layered warehouse execution and control system that ensures seamless coordination of the escala picking totes handling robots, and workstations. This system is composed of three intelligent layers;

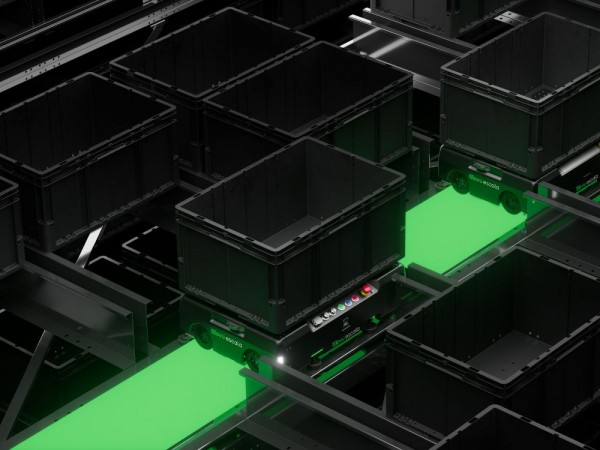

Inventory is stored in plastic totes within a high-density rack structure. Autonomous 3D escala robots retrieve these totes for inbound processing and order fulfillment. New inventory is added at designated goods-in workstations, where operators are guided to decant products into the correct tote or compartment;

Once completed, the escala robots return the totes to storage. Storage location selection is managed using availability data and performance-optimizing algorithms. SKU handling is based on quantity and location, with master data management handled by the customer’s WMS;

Achievement: Order processing happens at ergonomic goods-to-person (GTP) stations, where escala robots deliver totes directly to operators. This setup not only reduces walking time and physical strain but also:

- Speeds up picking operations;

- Improves order accuracy;

- Supports complex sequencing for multi-item orders;

Completed orders are temporarily stored in a smart shipping buffer, ensuring that outbound deliveries are dispatched in the correct sequence - a major boost for customer satisfaction and delivery reliability;

The system is designed with operational safety and uptime in mind. Automated zones are accessible only when safe, and service walkways and tools allow for quick recovery and maintenance without disrupting workflows. Preventative maintenance is performed outside the automated area, ensuring continuous performance and minimal downtime;

The result is a highly intelligent, scalable, and ergonomic warehouse automation solution that has revolutionized Papadeas S.A.’s logistics operations;

By integrating autonomous robotics with intelligent software, Papadeas S.A. has unlocked a new level of operational excellence;

Key business benefits include:

- Scalability to support future growth and product expansion;

- Flexibility to adapt to changing order profiles and seasonal demand;

- Cost-efficiency through reduced labor dependency and optimized storage;

- Customer satisfaction driven by faster delivery and fewer errors;

- Future-proof infrastructure ready to evolve with market needs;