ONE OF THE LEADING FOOD PRODUCTION COMPANIES - ATLANTIC GRUPA IS UPGRADING ITS LOGISTICS FACILITIES

Taking into consideration the higher operational costs in every warehouse and the lack of qualified warehouse operators, especially in smaller cities and industrial areas, international companies in Central and Southeastern Europe are opting for mechanization, automation, and even robotization of their storage systems and intralogistics processes. This is also the decision, Atlantic Grupa made regarding their distribution center, near the town of Šimanovci, in Serbia.

Atlantic Grupa is a leading international company, exporting products to more than 40 countries around the world. Markets in Croatia, Slovenia, Bosnia and Herzegovina, Serbia, Montenegro, and North Macedonia are particularly important for the group. Essential neural nodes in the company's logistics system are a total of 17 distribution centers located strategically in the Balkan Peninsula. These warehouses must operate quickly, effectively, and flexibly, serving more than 70 thousand points of sale where the company's products are available.

Efficient handling of heavy palletized loads is key for the food and beverages industrial sector and logistics. This is why, Atlantic Grupa chooses and continues its partnership with STAMH Group, in terms of warehouse equipment and warehouse intralogistics systems and processes organization.

The new warehousing system, designed, delivered, and installed by the teams of STAMH Group and STAMH d.o.o. in the Atlantic Grupa's distribution center near the town of Šimanovci in Serbia is a Radio Shuttle Racking System for pallets. This new semi-automated system is equipped with 2 robotic shuttle platforms.

The racking construction of these systems allows the maximum density of heavy pallets storage and, accordingly, maximum utilization of the warehouse volume. An important characteristic of this system is the way in which the robotic shuttle platforms transport the pallet in depth. Thus, it is not necessary for the lifting equipment to enter between the racks, and, accordingly, there is no need for working aisles in the racking construction.

Within little more than 570 square meters, the new Radio Shuttle Racking System provides storage and flexible operations for more than 1,600 pallets. As required by the customer, the Radio Shuttle System is organized in two different areas with 4 and 5 stacking levels in height, respectively. Zone number 1 of the racking system is for pallets with a height of up to 2.45 m, and zone number 2 is for pallets with a maximum height of up to 1.95 m.

Following specific customer requirements, STAMH Group engineering teams designed a special stacking level, to process pallets with a maximum height of 1.3 m.

The robotic, Radio Shuttle Platform can move at a speed between 0.8 and 1 m./s., and pallet handling at Atlantic Grupa's warehouse is now much faster. The new racking system allows double-sided stacking operations, working with FIFO or LIFO storage methods, according to the current market requirements and client’s needs.

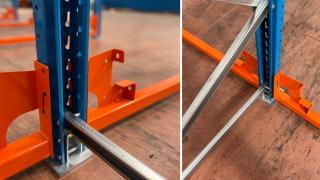

Of course, the system is equipped with side protectors for the double racking blocks and protectors for the columns of the racking system.

The main advantages of the Radio Shuttle pallet racking systems are the long-lasting industrial batteries of the shuttles, allowing more than 16 hours of active operation, while the time to fully charge the batteries is reduced to 3 hours. This type of system works flawlessly in cold warehouses, where temperatures are maintained at -20 °C. The depth of each shuttle tunnel in the system is practically unlimited.

Installing racking and storage systems with a Radio Shuttle platform results in a significant reduction in loading and unloading times, higher pallet buffering capacity, a reduction in the risk of accidents, and a significant reduction in the distances that warehouse operators and lifting equipment have to cover in the facility. Or briefly – efficient operations with less operational costs. These are just some of the reasons why more and more companies in Romania, Serbia, Greece, North Macedonia, Croatia, and other countries in the region choose the design and install mechanized and robotic racking systems from STAMH Group.

Learn more about Radio Shuttle technologies, here.